Introduction

Product development is the process by which new products are designed, developed and realised on the basis of previously defined goals and requirements. This refers to both an organisational unit and a process within a company in which developers, either as individuals or in teams, create concepts and designs for innovative products.

A product is the result of a manufacturing process, a tangible or intangible good that goes to market to satisfy the needs and requirements of users.

A (product-describing) model is a simplified, abstracted entity that has analogies to an object and formally represents its properties. In order to describe and specifically support the product development process, there are various models that describe the product development process from different perspectives.

This wiki is primarily based on the following model and sources:

Product development process model VDI 2221

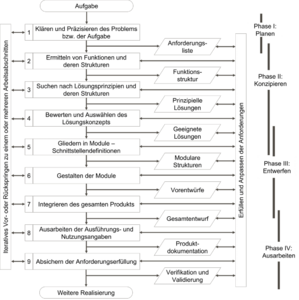

In guideline 2221, the Association of German Engineers presents a model for the development of technical products and systems, which views the development of products as a collection of different problems. The overview of the procedure can be seen in the figure. A subdivision into nine activities is proposed as follows.

- Activity 1 - Clarifying and itemising the problem or task: At the beginning of the product development process, the task or problem to be solved is clarified and specified. The task is reformulated into requirements from the developer's point of view, focussing on the core of the problem, which leads to an easier search for a solution.All available information is collected and supplemented and the requirements are then used for planning.The result is a structured collection of requirements on which the product development process is based.This can be adapted or supplemented during the process to take changes into account.

- Activity 2 - Determining functions and their structures: Determining functions and their structures is particularly important when developing new products and solving fundamental problems. It helps to find alternative and innovative solutions. For this purpose, the overall function and essential sub-functions are identified, whereby these are represented as a list for simple products and as function models such as function structures for complex products.

- Activity 3 - Searching for solution principles and their solutions: In this step, solution principles are sought for essential sub-functions. First, natural effects or alternatives such as algorithms from information technology are considered and then these are implemented using active principles. Other (secondary) functions are also recognised in the process. The result is one or more principle solutions.

- Activity 4 - Assessing and selecting the solution concept: As there are several solution concepts, these are continuously compared with the solution requirements. It is therefore necessary to select and assess between these options. This is done using various methods, such as defining assessment criteria and then comparing the solution concepts.

- Activity 5 - Subdivision into modules - interface definitions: The principle solutions are now subdivided into realisable modules. A system architecture (clarify concept) is created in which the main groups and elements are organised and connected via interfaces. This is particularly important for complex products. The results are, for example, sketches, graphs or plans.

- Activity 6 - Designing the modules: The relevant modules are realised and concretised here so that a rough shape can be selected. It is detailed to such an extent that it is still possible to select the optimum design at a later stage. Preliminary drafts of the relevant modules are obtained.

- Activity 7 - Integrating the product as a whole: he preliminary drafts of the models are brought together and finalised in this step. Groups and elements are added and designed, and all parts are linked together.This leads to an overall design in which all essential design specifications of the product are noted.

- Activity 8 - Elaborating the details of execution and use: he details of execution and use are worked out in detail, whereby there may be overlaps with previous activities. The result is the product documentation, for example in the form of technical drawings, operating instructions, user manuals or CAD models.

- Activity 9 - Assurance of the fulfilment of the requirements: Calculations, simulations or tests are carried out continuously to validate the current result with the requirements. The analysis can be divided into verification and validation: Verification checks whether the requirements are met and validation checks whether it is suitable for the intended purpose. Depending on the result, further steps may be necessary. Validation checks the extent to which the result, i.e. the product, is actually suitable for its intended use. Validation follows the question 'Is the right product being developed?'. Verification, on the other hand, checks whether the realised product meets the specifications. This follows the question 'Is the product being developed correctly?'.

These activities are typically divided into four phases:

- Phase 1: Clarify the task

- Phase 2: Conceptual Design - The development and presentation of the functions, the functional structure, the effects and effect carriers and their organisation as well as the effect structure.

- Phase 3: Embodiment Design - The development of graphic or written representations of the shape and arrangement of the elements/materials of a product.

- Phase 4: Final Design - The development of binding specifications of all details of the nature and use of a product

The definition of these activities and phases should not be viewed as strictly delineated. Rather, the activities can be subdivided into sub-activities and, like the phases, these can run into each other without a clear boundary and can also be run through several times or iteratively.

Referenced Sources

There are many works which present method collections. For this wiki, methods and their descriptions are based on the following main sources:

- VDI 2221 (1993). Methodik zum Entwickeln und Konstruieren technischer Systeme und Produkte.

- VDI 2221 - Blatt 1 (2019). Entwicklung technischer Produkte und Systeme Modell der Produktentwicklung.

- VDI 2221 - Blatt 2 (2019). Entwicklung technischer Produkte und Systeme Modell der Produktentwicklung

- Kumke, M. (2018). Methodisches Konstruieren von additiv gefertigten Bauteilen. Springer.

- Pahl, G. und W. Beitz (2013). Konstruktionslehre: Methoden und Anwendung. Springer-Verlag.

- Ehrlenspiel, K. und H. Meerkamm (2013). Integrierte produktentwicklung: Denkabläufe, Methodeneinsatz, Zusammenarbeit. Carl Hanser Verlag GmbH Co KG.

- Lindemann, U. (2009). Methodische Entwicklung technischer Produkte. Springer.

The base work for this collection is taken from:

- Fett, M. (2022). Erweiterung von DfAM Ansätzen durch hybrid-integrierte additive Fertigungstechnologien. Magisterarbeit.Technische Universität Darmstadt.